I intended for this blog to be full of witty banter, but I can't be witty and

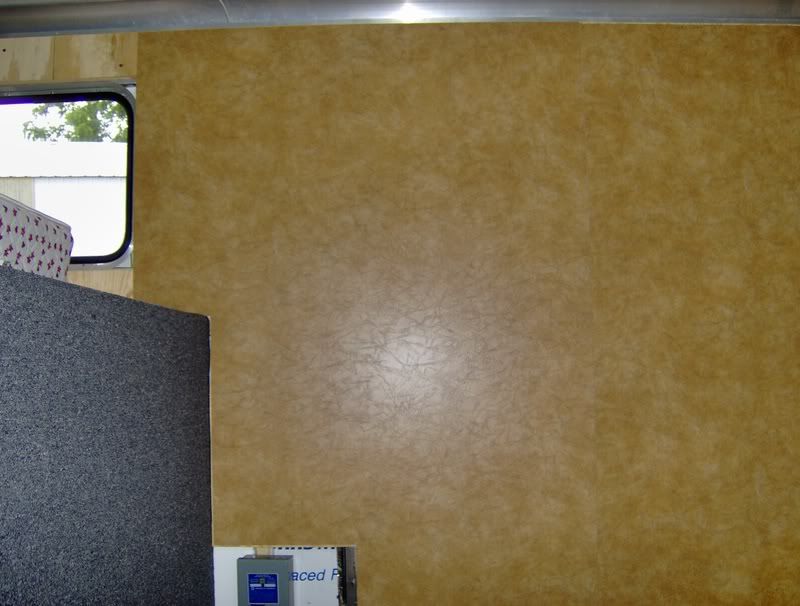

The past few months have been a whirlwind of activity. The work on the barn has consumed most of our time, and the work still continues. I've been lax these past few weeks, but I will get back at it this weekend. Kinda got burnt out. I really should take some new pics to show the progress, but I hate our camera so much that I avoid it. A new one of those is on the list too, but that list is long.

Our trusty Buick decided to die last week. Well, maybe not die, but it sure requires some intensive care. The head gasket failed, which allowed all of the coolant to enter through the intake valve on the first cylinder at an alarming rate and be expelled out through the exhaust pipe in a massive cloud of stinky steam and white smoke. It's been at the garage for three days. I shudder to think.....

The weather has been unseasonable wonderful for February in Wisconsin. We've had temps above freezing everyday for the last week. I believe Tuesday was in the 50's. The record snowfalls that we received in December are almost just memories. Dirty grey melting piles of memories. I'm sure the mild temps are only temporary, but we'll enjoy them while they last.

The mild temps have allowed Sara to spend much more time working the horses and readying them for the upcoming show season. Jin has been learning all about counter-cantering and flying lead changes. He has picked up on it really well. If he continues to learn and get stronger with his new teachings he's sure to hold his own in the show ring this season.

Kirby is growing up to be a big boy. He's going to have a stockier build than Jin, but with movement just as nice. The other day Sara was working with Kirby on the line at a trot and all I could do was smile. He's got such nice natural movement already. I hope he turns some heads this summer, too.

Hank is a funny one. He knows that the younger boys have getting worked so he has been hanging out by the small gate a lot. The small gate is the one nearest the barn, and it's also the gate farthest from the food. Anyone that knows Hank will understand that having him voluntarily leave the hay pile is not a normal thing. His pathetic pouting earned him some riding time with Sara, and he sure seemed to enjoy the attention. He's going to be eleven this year (hard to believe), and he still tries to get away with the same old tricks he has been trying to get away with for the last six and a half years, but he does this with less vigor. But he still tries.

That's about all for now. Off to buy more batteries for that rotten camera.